Axial fans, with their simple yet effective design, have long been stalwarts in the world of airflow. These fans operate by drawing air through the axis of the fan blades, creating a linear airflow pattern. The efficiency in moving large volumes of air with relatively low pressure makes axial fans well-suited for applications where consistent, unobstructed airflow is paramount.

Axial fans shine in scenarios where general ventilation is the primary objective. Their ability to move air continuously is well-suited for applications like cooling electronic components, providing fresh air circulation in buildings, and maintaining comfortable environments. Axial fans are particularly effective in situations where the resistance to airflow is minimal.

One of the key advantages of axial fans is their space-friendly design. They are generally more compact, making them suitable for applications where space is at a premium. Their streamlined construction allows for easy integration into various systems without imposing significant spatial constraints.

The Power of Centrifugal Force: AC Centrifugal Fans Take the Stage

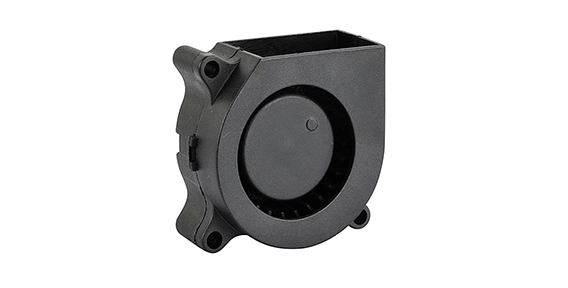

AC centrifugal fans bring a different dimension to the airflow game by harnessing the power of centrifugal force. Unlike axial fans, these fans draw air into the center and then expel it at a right angle to the intake. This centrifugal motion allows for higher pressure generation, making them well-suited for applications with higher resistance to airflow.

The standout feature of AC centrifugal fans lies in their ability to excel in applications with higher resistance. This makes them the preferred choice in scenarios where airflow encounters obstacles, such as in HVAC systems, air filtration units, or industrial processes. AC centrifugal fans can maintain efficiency even when faced with increased air resistance.

AC centrifugal fans offer versatility in blade configurations, allowing for customization based on specific application requirements. Forward-curved blades are often used for high airflow, while backward-curved or radial blades are employed for higher pressure applications. This adaptability in blade design enhances the flexibility of AC centrifugal fans in addressing diverse airflow challenges.

Comparing Applications: Axial vs. AC Centrifugal Fans

Axial fans find their niche in cooling electronic components, where the emphasis is on consistent and relatively unobstructed airflow. Computers, servers, and electronic enclosures often leverage the efficiency of axial fans to prevent overheating. The space-friendly design of axial fans makes them suitable for integration into compact electronic devices.

In industrial settings and air filtration units, where air resistance can vary significantly, AC centrifugal fans in industrial axial fans take center stage. Whether it's exhausting fumes, maintaining airflow in industrial ovens, or driving air through intricate filtration systems, the power of centrifugal force makes these fans indispensable in high-resistance applications.

In conclusion, the choice between axial and AC centrifugal fans depends on the specific requirements of the application. Axial fans excel in scenarios where unobstructed, continuous airflow is the primary goal, making them ideal for general ventilation and cooling electronic components. The key is to understand the unique characteristics of each fan type and select the one that aligns with the demands of the particular airflow challenge at hand. As technology advances, both axial and AC centrifugal fans continue to play integral roles in ensuring efficient and tailored airflow solutions across diverse industries.

EN

EN

+

+

+

+

+

+