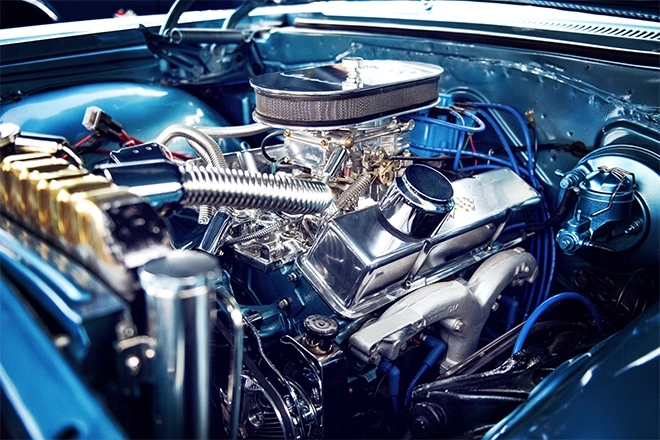

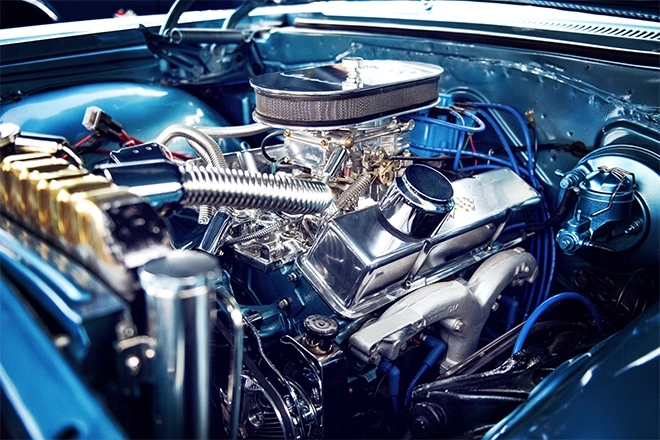

Car engine fans play a crucial role in maintaining optimal engine temperature and preventing overheating. Over the years, advancements in materials and design have revolutionized the construction of car engine fans, ensuring improved performance, durability, and efficiency. In this article, we will explore the evolution of materials in car engine fan construction, design innovations, and the integration of materials and design for optimal performance.

The Evolution of Materials in Car Engine Fan Construction

From the early days of car manufacturing to the present, materials used in car engine fan construction have undergone significant transformations. Initially, steel was the primary material choice due to its strength and durability. However, steel fans were heavy and cumbersome, often causing drag on the engine and reducing fuel efficiency.

In recent years, with a focus on lightweight materials and energy efficiency, manufacturers have shifted towards using composite materials, such as fiberglass and carbon fiber, for the car engine fan. These materials offer high strength-to-weight ratios, allowing for reduced weight and improved performance. Carbon fiber particularly stands out as a lightweight, durable, and corrosion-resistant material, enhancing both the efficiency and lifespan of car engine fans.

Design Innovations in the Car Engine Fan

In addition to material advancements, design innovations have played a pivotal role in enhancing the performance of car engine fans. Traditional fixed fan blades have given way to variable pitch blades, which are capable of adjusting their angle to optimize airflow and reduce engine load. This design innovation allows the fan to react dynamically to engine cooling requirements and provides improved efficiency and noise reduction.

Furthermore, manufacturers have started incorporating brushless electric fan motors. Compared to traditional belt-driven fans, brushless electric fans are more energy-efficient and can be controlled electronically. These fans can be programmed to adjust speed according to engine temperature, reducing power consumption and providing precise control over cooling.

Integrating Car Engine Fan Materials and Design for Optimal Performance

To maximize the benefits of both material advancements and design innovations, manufacturers have been striving to integrate them cohesively. By combining lightweight materials with aerodynamic designs, the automotive cooling fan can offer optimal performance and efficiency.

Efficient design techniques, such as the implementation of shrouds, help to direct airflow more effectively, reducing wasteful air spillage and improving overall cooling performance. Additionally, the use of computational fluid dynamics (CFD) allows for precise modeling and testing of various designs, further optimizing the fan's performance.

Moreover, the integration of advanced technology has allowed for the development of smart fans. These fans utilize temperature sensors and sophisticated control systems to constantly adapt and adjust fan speed according to cooling requirements. This intelligent approach not only enhances efficiency but also minimizes wear and tear on the fan, extending its lifespan.

Materials and design innovations have propelled car engine fans into the realm of enhanced performance, durability, and energy efficiency. The evolution from heavy steel to lightweight composites and the introduction of variable pitch blades, brushless electric motors, and smart technology have revolutionized how these fans operate. As car manufacturers continue to push the boundaries of material science and design, car engine fans will continue to evolve, ensuring optimal performance and engine cooling in the years to come.

EN

EN

+

+

+

+

+

+