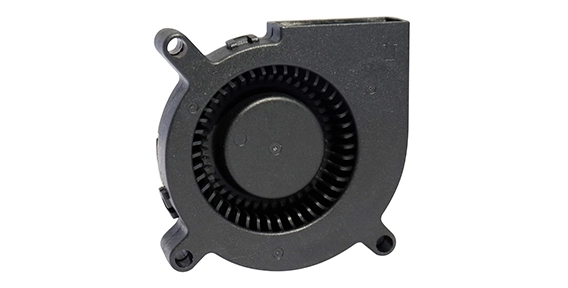

Cleanrooms are specialized environments where the control of airborne particles, contaminants, and other pollutants is of utmost importance. These controlled environments are used in various industries such as pharmaceuticals, biotechnology, electronics manufacturing, and aerospace, where maintaining air quality and preventing contamination is vital for the production process. One critical component in ensuring a clean and sterile environment is the centrifugal blower fan.

Centrifugal Blower Fan Design Considerations for Cleanroom Compatibility

When designing a centrifugal blower fan for cleanroom applications, several key considerations must be taken into account. First and foremost, the fan must be able to provide sufficient air movement and ventilation while maintaining low levels of noise and vibration. This is crucial as excessive noise and vibrations can disrupt the sensitive equipment and delicate processes within the cleanroom.

Additionally, the blower fan should be designed to minimize the generation and dispersal of particles. This involves using smooth and streamlined designs, as well as materials that are non-shedding and easy to clean. The fan should also have tight seals to prevent any leakage of air and contaminants into or out of the cleanroom.

Centrifugal Blower Fan Contamination Prevention and Control

Contamination prevention and control are essential aspects of cleanroom operations. Centrifugal blower fans play a critical role in ensuring that the air within the cleanroom remains free from particles, dust, and other contaminants. By effectively circulating the air and removing impurities, these fans help maintain the required air quality standards.

To prevent contamination, centrifugal blower fans for cleanrooms should be equipped with efficient filters. High-efficiency particulate air (HEPA) filters are commonly used in cleanrooms to remove particles as small as 0.3 microns with an efficiency of 99.97%. These filters are installed in the inlet of the fan, ensuring that the air passing through the fan is clean and free from contaminants.

Regular maintenance and cleaning of the axial cooling fan are also crucial to prevent contamination. This includes inspecting and replacing filters when necessary, as well as regularly cleaning the fan blades and components to remove any accumulated dust or particles.

Centrifugal Blower Fan Customization for Unique Requirements

In some cleanroom applications, unique requirements may dictate the need for customized centrifugal blower fans. For example, certain industries may require the use of explosion-proof fans to prevent the ignition of flammable materials or gases within the cleanroom. These fans are designed with specific electrical requirements and safety features to minimize the risk of sparks or explosions.

Moreover, cleanrooms operating at extreme temperatures, such as in pharmaceutical freeze-drying processes or semiconductor manufacturing, may necessitate the use of high-temperature centrifugal blower fans. These fans are designed with heat-resistant materials and insulation to ensure optimal performance and reliability under extreme conditions.

Centrifugal blower fans can also be customized to meet specific airflow and pressure requirements of different cleanroom classifications. By tailoring the fan design to the specific needs of the cleanroom, operators can ensure efficient air circulation and achieve the desired air quality standards.

In conclusion, centrifugal blower fans are crucial components in achieving clean and sterile environments in various industries. Their design should consider compatibility with cleanroom requirements, prevention of contamination, and customization for unique needs. By selecting the right centrifugal blower fan and implementing proper maintenance procedures, cleanroom operators can ensure optimal air quality control and minimize the risk of contamination in their facilities.

EN

EN

+

+

+

+

+

+