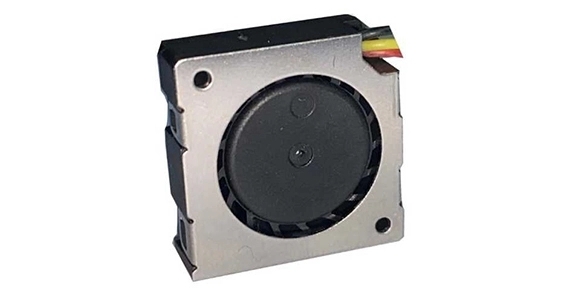

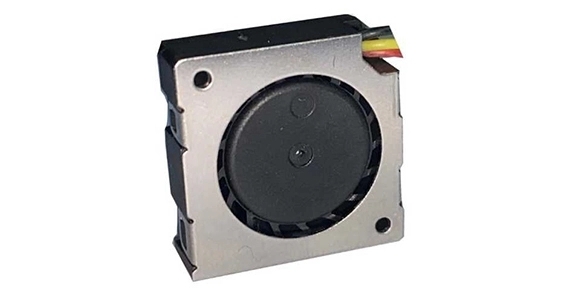

Pressure blowers, also known as blower fan coolers, are widely used in various industries for multiple applications. These high-pressure fans play a crucial role in several processes, including ventilation, cooling, and drying. Understanding the dynamics of pressure blowers is essential for optimizing their performance and ensuring their safe operation. In this article, we will delve into the role of noise reduction in blower fan cooler technology, the regulations and safety measures for using these fans in different industries, and tips for choosing the right blower fan cooler for optimal performance.

The Role of Noise Reduction in Blower Fan Cooler Technology

One of the major concerns associated with pressure blowers is the noise they generate during operation. Excessive noise levels can hinder productivity, cause discomfort to workers, and even lead to hearing damage. Therefore, noise reduction technology has become a crucial aspect of blower fan cooler design.

Various techniques are employed to reduce noise in blower fan coolers. These include employing sound insulation materials, optimizing blade design, and incorporating silencers or attenuators into the fan system. Sound insulation materials are used to minimize the transmission of sound waves and vibrations from the blower. Blade design optimization involves reducing blade turbulence and eliminating sources of noise generation. Adding silencers or attenuators to the fan system helps to reduce noise levels by absorbing and dissipating sound energy.

Regulations and Safety Measures for Using Blower Fan Cooler in Different Industries

When using blower fan coolers in various industries, it is essential to adhere to regulations and safety measures to ensure safe operation. Different industries may have specific guidelines that need to be followed to prevent accidents, protect workers, and maintain environmental standards.

For example, in the manufacturing sector, where blower fan coolers are commonly used for cooling processes, it is essential to ensure proper maintenance and inspection of the fans to avoid any mechanical failures that could lead to accidents. Additionally, operators should be provided with proper training on the safe operation of industrial axial fans, including understanding the risks associated with high-pressure systems and the use of personal protective equipment.

In the construction industry, where pressure blowers are often utilized for ventilation purposes, ensuring proper installation and maintenance of the fans is crucial. Proper ventilation is essential for maintaining a safe and healthy working environment by preventing the accumulation of hazardous gases and maintaining air quality.

Choosing the Right Blower Fan Cooler for Optimal Performance

Selecting the right blower fan cooler is vital for achieving optimal performance and efficiency in various applications. Here are a few factors to consider when choosing a blower fan cooler:

Airflow requirements: Determine the required airflow rate for the specific application to ensure that the selected blower can deliver the necessary volume of air.

Pressure requirements: Consider the pressure requirements of the system to select a blower fan cooler that can deliver the desired pressure.

Energy efficiency: Look for blower fan coolers that are energy-efficient to minimize power consumption and reduce operational costs.

Noise levels: Consider the noise output of the fan to ensure it aligns with the noise restrictions of your workplace.

Maintenance requirements: Understand the maintenance requirements of the blower fan cooler to ensure that it can be easily maintained and serviced.

By considering these factors, organizations can choose the right blower fan cooler that meets their specific needs, ensuring optimal performance and longevity.

Blower fan coolers play a crucial role in various industries, supporting processes such as ventilation, cooling, and drying. Understanding their dynamics, implementing noise reduction technology, adhering to regulations and safety measures, and choosing the right fan for optimal performance are all essential steps towards efficient and safe operation in industrial settings.

EN

EN

+

+

+

+

+

+