Centrifugal blower fans are essential components of many industrial systems that require the movement of air or gases. Their main function is to increase the pressure or velocity of the air/gas stream, enabling it to be transported throughout the system. However, the design of these fans plays a crucial role in determining their efficiency and overall system performance. In this article, we will explore the various aspects of centrifugal blower fan design and their impact on system efficiency.

Understanding the Fundamentals of Centrifugal Blower Fan System Design

To comprehend the influence of centrifugal blower fan design on system efficiency, it is essential to understand the fundamentals of their system design. A basic centrifugal blower fan consists of an impeller, housing, inlet/outlet ducts, and bearings. The impeller is the heart of the fan and is responsible for generating the airflow through its rotational motion.

The Crucial Role of Impeller Design in Centrifugal Blower Fan Efficiency

The design of the impeller has a significant impact on the efficiency of the centrifugal blower fan. Various factors, including the blade shape, angle, and size, determine the fan's ability to generate airflow and increase pressure. Proper impeller design can minimize energy losses due to turbulence and maximize the fan's ability to deliver the required airflow. Manufacturers like XIE HENG DA understand the importance of impeller design and offer high-quality centrifugal blower fans that prioritize efficiency and performance.

The Influence of Bearing Types and Design on Centrifugal Blower Fan Efficiency

Another critical aspect of axial cooling fan design that affects system efficiency is the type and design of the bearings. Bearings support the rotating shaft of the fan and facilitate smooth rotation with minimal friction. The choice of bearing type, such as ball bearings or roller bearings, can impact the overall efficiency of the fan. Additionally, proper bearing design and maintenance play a vital role in reducing energy losses and prolonging the fan's lifespan.

Centrifugal Blower Fan Efficiency and System Performance

The efficiency of centrifugal blower fans directly impacts the overall system performance. Inefficient fan design can lead to increased energy consumption, higher operating costs, and reduced productivity. On the other hand, well-designed fans can provide optimal airflow, reduce energy consumption, and enhance the productivity of industrial processes. Therefore, it is crucial to consider the design and efficiency of centrifugal blower fans when selecting and installing them in industrial applications.

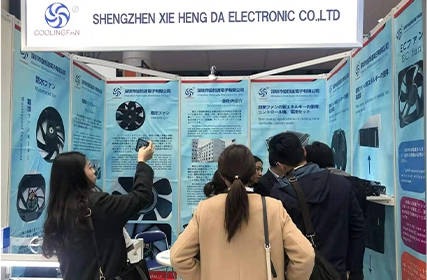

XIE HENG DA: Delivering Efficient Centrifugal Blower Fans

When it comes to centrifugal blower fans, XIE HENG DA is a renowned brand that prioritizes efficiency and performance. Their high-quality fans are designed with precision to ensure maximum airflow delivery with minimum energy consumption. With a wide range of centrifugal blower fan options, XIE HENG DA offers tailored solutions for various industrial applications.

In conclusion, the design of centrifugal blower fans has a substantial impact on system efficiency. The impeller design, bearing types, and overall fan design significantly influence the energy consumption, airflow delivery, and overall performance of the system. Manufacturers like XIE HENG DA understand the importance of efficient fan design and offer high-quality centrifugal blower fans that optimize system efficiency and productivity. By selecting the right fan design and maintaining it properly, industries can enhance their system's performance while minimizing energy consumption.

EN

EN

+

+

+

+

+

+