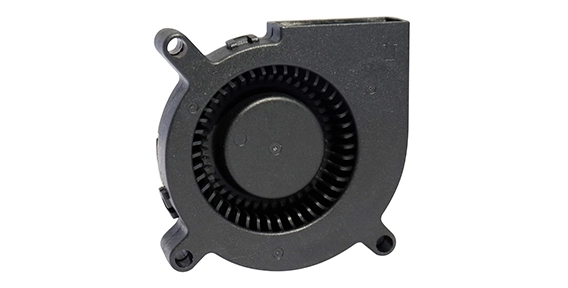

Centrifugal blower fans are widely used in various industries, ranging from HVAC systems to industrial processes. These fans play a crucial role in maintaining airflow and providing efficient ventilation. One crucial component of centrifugal blower fans that often goes unnoticed is the bearing system. Bearings are the crucial nexus of stability and motion in these fans, and their selection plays a significant role in the performance and reliability of the equipment.

Bearings: The Crucial Nexus of Stability and Motion in Centrifugal Blower Fan

In a centrifugal blower fan, the bearing system supports the rotating impeller, allowing it to spin freely and generate the desired airflow. The bearing design must provide stability and smooth operation while enduring the radial and axial loads exerted during fan operation. Therefore, selecting the right bearings is vital for ensuring optimal performance and longevity.

Centrifugal Blower Fan Angular Contact Ball Bearings: Addressing Axial Loads

Centrifugal blower fans often experience substantial axial loads due to the nature of their operation. These axial loads are caused by the pressure difference across the impeller, which creates a thrust force. To address this axial load, angular contact ball bearings are commonly used in centrifugal blower fans. These bearings can withstand both radial and axial loads while maintaining accurate alignment between the inner and outer rings.

Angular contact ball bearings have a contact angle between the ball and raceway that allows them to support both radial and axial loads simultaneously. This design ensures more uniform load distribution and minimizes the risk of premature bearing failure. By selecting angular contact ball bearings with appropriate load capacities, manufacturers can enhance the overall performance and reliability of centrifugal blower fans.

Centrifugal Blower Fan Environmental Considerations: Protection Against Contaminants

Centrifugal blower fans are often exposed to harsh environmental conditions, including dust, moisture, and chemicals. These contaminants can infiltrate the bearing system, leading to premature wear, increased friction, and ultimately, bearing failure. To combat these environmental challenges, manufacturers should consider environmental protection measures when selecting bearings for the axial cooling fan.

One common solution is to use sealed or shielded bearings that prevent the ingress of contaminants into the bearing raceways. Sealed bearings provide a physical barrier against dust and moisture, while shielded bearings offer partial protection while allowing some airflow for cooling purposes. Alternatively, high-quality bearings with effective labyrinth seals are also capable of providing reliable protection against contaminants.

Additionally, some manufacturers offer special coatings or treatments for their bearings, providing added protection against corrosion and chemical exposure. These coatings can prolong the service life of the bearings and ensure the continued smooth operation of the centrifugal blower fan.

In conclusion, the selection of bearings in centrifugal blower fans is crucial for the overall performance and reliability of the equipment. Choosing the right bearings, such as angular contact ball bearings, can effectively address axial loads and ensure stable operation. Furthermore, considering environmental protection measures, such as sealed or shielded bearings, can enhance the longevity of centrifugal blower fans by preventing the ingress of contaminants. By paying attention to bearing selection, manufacturers can optimize the performance and efficiency of centrifugal blower fans, offering reliable and effective ventilation solutions in various industries.

EN

EN

+

+

+

+

+

+