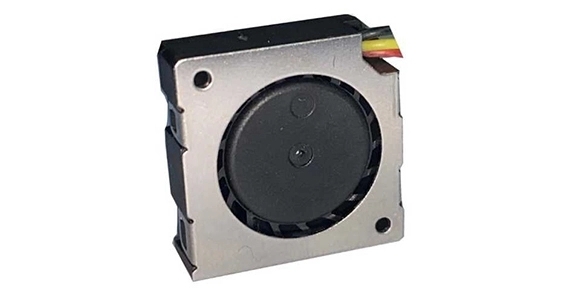

In the demanding landscapes of industrial environments, the need for robust and efficient cooling solutions is paramount. DC blower fans emerge as indispensable allies, providing reliable heat dissipation in harsh conditions. This exploration delves into the unique features and applications of DC blower fans tailored for the challenges posed by industrial settings.

The Role of DC Blower Fans in Industrial Cooling

DC blower fans, also known as radial fans, play a pivotal role in maintaining optimal temperatures within industrial setups. Unlike traditional axial cooling fans, the blower design of DC fans enables them to generate a concentrated, radial airflow. This capability proves particularly advantageous in environments where consistent and directed cooling is essential, such as in machinery, control panels, or electronic enclosures.

In industrial applications, the axial cooling fan's limitations in providing focused airflow make the DC blower fan a preferred choice. The ability to channel air precisely to specific components ensures effective heat dissipation in systems operating under extreme conditions.

DC Blower Fan: Design Features for Industrial Resilience

DC blower fans engineered for harsh industrial environments boast a range of design features that set them apart. The robust construction of these fans is often reinforced with durable materials, providing resistance to factors such as dust, moisture, and temperature fluctuations. This resilience is crucial in environments where machinery is exposed to elements that could compromise the integrity of traditional cooling solutions.

The axial cooling fan, although effective in certain scenarios, may struggle to contend with the challenges posed by industrial settings. In contrast, the radial airflow design of DC blower fans allows them to operate efficiently even in environments laden with airborne particles or subjected to elevated temperatures, making them a stalwart choice for industrial cooling applications.

DC Blower Fan: Thermal Management in Challenging Conditions

Industrial environments often present thermal management challenges that demand specialized solutions. DC blower fans excel in these conditions, providing precise and powerful airflow to dissipate heat generated by machinery and electronic components. The axial cooling fan, while effective in less demanding scenarios, may fall short in applications where targeted cooling is imperative.

One notable feature of DC blower fans designed for industrial use is their ability to operate at variable speeds. This adaptability allows users to fine-tune the airflow to match specific thermal requirements, ensuring optimal cooling efficiency in diverse and dynamic industrial settings. Whether cooling electronic control systems or machinery components, the DC blower fan's versatility shines in environments where thermal management is a critical consideration.

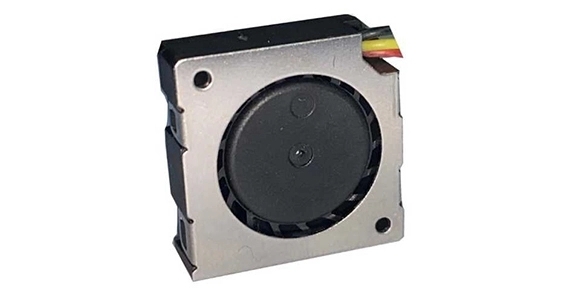

DC Blower Fan: Applications Across Industrial Sectors

DC blower fans find applications across a spectrum of industrial sectors, contributing to the reliability and longevity of critical equipment. In manufacturing plants, these fans play a crucial role in cooling CNC machines, ensuring precision and consistency in production processes. In the energy sector, DC blower fans are employed to cool electrical components in power generation and distribution systems, where efficiency and reliability are paramount.

The versatility of the axial cooling fan may be limited in such scenarios, making DC blower fans the preferred choice for industrial applications where durability and precision cooling are non-negotiable. The ability to withstand harsh conditions and provide directed airflow positions them as essential components in the arsenal of cooling solutions for industrial settings.

When selecting DC blower fans for harsh industrial environments, considerations go beyond traditional cooling parameters. Factors such as ingress protection (IP) ratings, corrosion resistance, and the ability to operate in extreme temperatures become pivotal. Regular maintenance routines also play a crucial role in ensuring the longevity and effectiveness of DC blower fans in challenging conditions.

In conclusion, the utilization of DC blower fans in harsh industrial environments reflects a strategic choice in the pursuit of efficient and resilient cooling solutions. The axial cooling fan, while suitable for certain applications, may find its limitations in the face of industrial challenges. The specialized design and features of DC blower fans position them as essential components, ensuring the seamless operation of machinery and electronic systems in the demanding landscape of industrial settings.

EN

EN

+

+

+

+

+

+